RevEng Against Obsolescence

Reverse Engineering Services

Undocumented Circuit Card

Documentation

Shawtronics USA offers expert, professional electronic diagnostic services of integrated circuit cards to produce NET Lists and Schematics of obsolete electronic circuit cards and electrical mechanical devices.

Example Case Studies

Case Study #1

Case Study #2

Learn More

"Obsolete does not equal delete."

~Some unknown person

Case Study #1

Developing schematics and supporting data for undocumented circuit boards.

Schematics and other technical data make it much easier and faster to test, repair and remanufacture circuit boards.

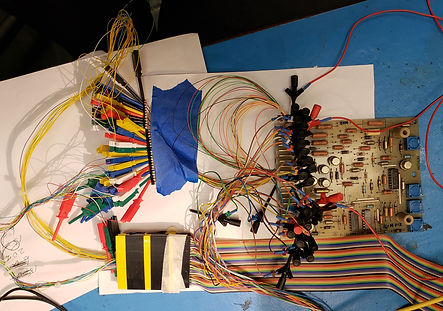

This relatively simple circuit board has a total of 312 connection points. Each of these points gets connected to a 1024-channel reverse engineering instrument using clips, probes, hooks and/or solder. Boards with more than 1024 connections can be

connected in sequences, or more channels can be added to the reverse engineering system.

The reverse engineering system and its software then catalogs all the traces on the board. The system then merges a list of all the components with its catalog of the traces to produce what is known as a netlist.

CAD software interprets the netlist to produce a schematic for testing and repair. If no replacement boards are available and more boards need to be manufactured, CAD software can take the schematic a step further to produce a Gerber

file. A Gerber file is what a circuit board fabricator needs to reproduce a board.

The photo above shows a board that was Reverse Engineered at Shawtronics USA using high tech. precision circuit scanning equipment.

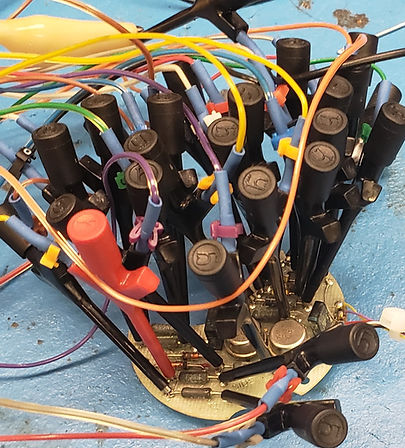

The photo to the right shows the undocumented board as the first two dozen or so test clips are connected to component leads.

Once all the connections are made the system will scan each point and find all its connected points.

The information is stored along with the components list for use in generating the Netlist that will in turn become the schematic.

It took Shawtronics USA about 60 hours to create the schematic for this board. That includes system setup, listing the components, making connections, generating the netlist and the schematic, then combining the schematic with supporting information to make a technical guide for the circuit board.

It may seem like a lot of time, but without the reverse engineering system it could take something on the order of 60 days to go point by point and manually identify and record all the connections.

The completed schematic and supporting information eliminates most of the obstacles that can be encountered in troubleshooting and enables testing and repair of boards in much less time than when there was no documentation.

The photo below shows the circuit board with all connection points and components hooked up to the reverse engineering equipment.

Now the reverse engineering system can be put

to work finding and recording all connections associated with each point.

The reverse engineering system assembling

information about the connected board.

RESULTS

Component Layout

Schematic

Learn More

Case Study #2

~Some unknown person

"Obsolescence is the seed of Nostalgia."

Case Study #2

Developing schematics and supporting

data for abandoned technology.

This little device has faithfully served as a component of a larger device for decades.

Now they are no longer made and rather than scrapping the entire device a little reverse engineering saves the day.

The inner circuit cards are encapsulated in epoxy which must be removed without any damage to the components or the components labels.

After careful removal of the epoxy the circuit cards are revealed and the labels easily read.

Probes are systematically attached for diagnostics.

A schematic document is produced,

and a component layout.

With this documentation and the physical device itself, repairs can be made and even remanufacture can be done.

Case Study #1

Reverse Engineering Services

What we will do for you.

1) Identify and log each component , to include all data spec sheets.

Source out each component and pricing of each component . Generate total cost for parts to

manufacture the cards.

2) Layout in CAD , the location and assigned id number for each component on the circuit cards.

3) Use equipment specifically designed to scan the circuit cards and obtain the interconnect between

each component to generate a Net List of the interconnections between each component and connector.

4) Complete the scan and develop a schematic from the Net List that is generated by

the reverse engineering equipment and program.

A) To be used for trouble shooting and Diagnostics of the circuit card.

B) To be use to remanufacture the circuit card.

5) Generate a 3D CAD file (DXF) for each card and the components that are on the circuit cards.

These files will need to be sent to the circuit board manufacturer to layout the traces and holes to develop

gerber files in conjunction with the net list of interconnect between the parts.

NOTE: Circuit card assembies may have very tight tolerances of dimensions and positions of

the constraint holes where they are bolted into the next higher assembly, as well as the positions

of the interconnection tabs and connectors.

6) The company that is chosen to manufacture the circuit boards will be given all the files required for

them to layout the circuit card.

Inclusive of:

a) 3d cad files (DXF)

b) Part numbers of components,

c) Net list and schematics

d) Photos of the cards

7) All files and data derived from the project will be sole proprietary property of the Client bound by non disclosure by Shawtronics USA without permission.

What we need from you.

Call us and talk to a real person at (240) 946-1124, or fill out the form below. You can also email us at sales@shawtronicsusa.com.

My Grandpa will fix you up!